Una impresora 3D es capaz de realizar réplicas de diseños en 3D, creando piezas o maquetas volumétricas a partir de un prototipo previamente diseñado en un ordenador y tras la necesidad de hacer que los archivos 2D, fueran prototipos reales en 3D.

En un inicio la impresión 3D se aplicó en sectores como la arquitectura y el diseño industrial, pero actualmente su uso se está expendiendo a la fabricación de todo tipo de objetos

En la actualidad, las multinacionales y empresas más importantes, recurren a las impresoras 3D por su flexibilidad y el ahorro de costes.

La fabricación aditiva o 3D trae consigo una nueva forma de trabajar en tanto en diseño como en producción para muchas empresas de sectores diversos. Esta tecnología ha tenido en los últimos tiempos un avance muy importante debido a las constantes innovaciones en software y hardware.

En este momento las piezas que se obtienen mediante las impresoras 3D y que son usadas tanto en automoción como en aeronáutica o en el sector de construcción ferroviaria, cada vez presentan resultados más precisos, pero para conseguir un acabado perfecto en las piezas, es necesario contar con un proceso posterior para tratar esta superficie y el mejor método para ello es recurrir a un proceso de chorreado.

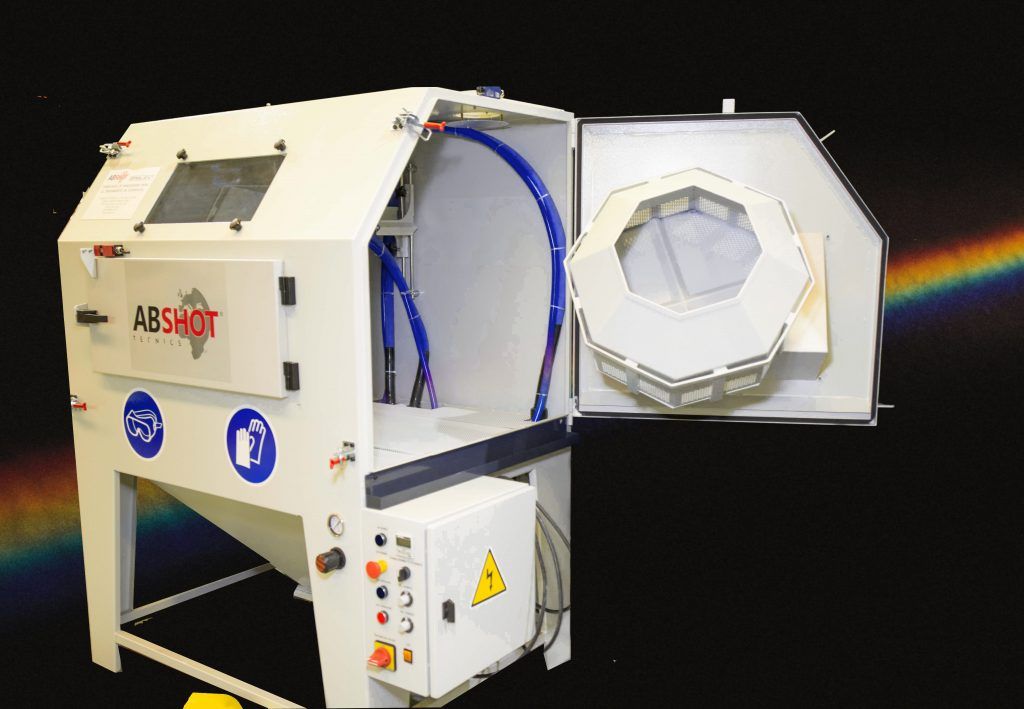

Una de las especializaciones en cuando a maquinaria se refiere es el diseño y producción de chorreadoras para tratamiento superficial post-impresión, consiguiendo acabados definidos y en piezas 3D FFF, consiguiendo piezas acabadas según las necesidades del consumidor final.

El proceso de chorreado que sigue a fabricación aditiva o impresión 3D, pretende que las piezas salidas de un proceso de impresión estén totalmente acabadas.

Lo que conseguimos principalmente con este proceso de chorreado es homogeneizar la superficie y los acabados de la pieza, tanto si se trata de eliminar rebabas, redondeando esquinas conseguir una pieza acabada con una superficie pulida y lisa o bien preparar estas piezas para su recubrimiento posterior o bien para ser ensambladas en un conjunto completo.

¿Necesitas ayuda?

Nuestro equipo de Ventas estará encantado de ofrecerte una solución adaptada a tu negocio.

Contacta con Ventas